Loopwheels

Loopwheels worked with TECHNIA Simulation to enhance product characteristics and develop its next-gen product.

The Client

Loopwheels are vibration-reducing wheels, designed, engineered and made in Nottinghamshire, UK by Sam Pearce and his team at Jelly Products Ltd.

The Challenge

While Loopwheels have gone from strength to strength over the past few years, the team is constantly looking to improve the design and overcome any limitations. One such limitation has been the product having a low lateral stiffness.

The Results

With a virtual prototype and simulation developed in partnership with the TECHNIA Simulation, Sam and his team were able to find an optimized spring shape and a composite layup able to improve the wheel performance. This resulted in a 33% increase in lateral stiffness.

The redesign of key components, such as the metal hub, and the use of carbon-fiber composites allowed to further reduce the weight by 27%, making it one of the lightest wheels of this kind in the market. The vibration-reducing characteristics improved as well, with a difference of up to 70% compared to a traditional spoked wheel.

Back in 2007, Designer and Inventor, Sam Pearce had a moment of inspiration as he sympathised with a young mother struggling with her pushchair. While waiting for his flight from Eindhoven, he sketched his idea out idly in his notepad. Five years later, when Kickstarter came to the UK, Loopwheels became one of the first inventions to receive full backing and begin production.

Reinventing the wheel

In little more than a month, Sam’s design for a wheel with a built-in suspension system, provided by composite material springs, had raised over 150% of their initial funding target. By the nine month mark, production on all project-backers’ wheels had been completed.

At their first bike show, three days before their original Kickstarter was launched, Sam was approached by GB Basketball Paralympian, Helen Turner. She, among many other wheelchair users, recognised the significant difference that Loopwheels could make to the performance of her chair.

So, in February 2015, Loopwheels’ new project began. This time they were funded in under a month, and nominated for the Design Museum’s, “Design of the Year 2015”.

Making a product for the individual

A continued aspect of Loopwheels’ success is that they listen to their customers. And, since initial production, a number of alterations in design, including the availability of customisation options, have been added. Most notably, and by public demand, there are now 20 different options available for the push rim of your Loopwheels.

The team at Loopwheels are building products specifically for end-users. These are products that are affecting genuine, individual, often immeasurable change in peoples’ lives. The Loopwheel has proven capable of providing the necessary suspension to overcome the onset of fatigue, back pain, and muscular spasticity during general use. Which, for some, means the option of leaving the house without fear of inducing a painful episode or causing permanent nerve damage.

Composite Knowledge and Simulation Experience

Loopwheels have gone from strength to strength over the years. And, in the last three, they have been working in partnership with the TECHNIA Simulation to enhance the product characteristics and most recently to develop the next generation of Loopwheels.

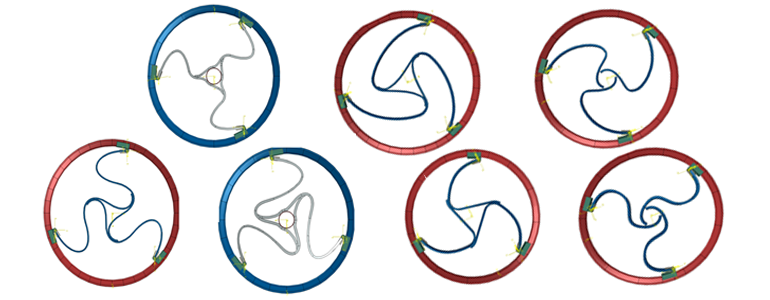

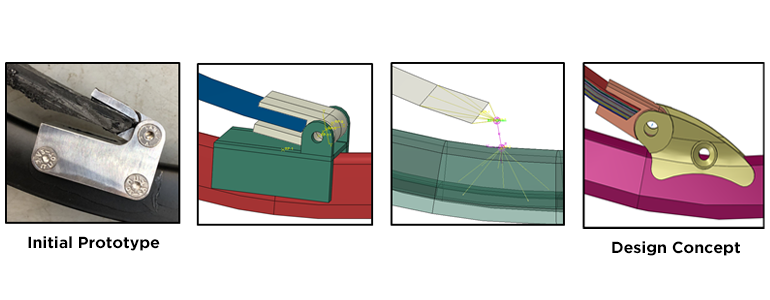

The use of a virtual prototype has proven to be fundamental in finding a new improved design that would also overcome the current limitations, such as having a low lateral stiffness. It also meant that new ideas, designs and materials could be tested without the need to create expensive physical prototypes.

Key Results

One of the key objectives of the simulation-driven redesign was to find an optimised spring shape and a composite layup able to improve the wheel performance. This resulted in a 33% increase in lateral stiffness.

The redesign of key components, such as the metal hub, and the use of carbon-fiber composites allowed to further reduce the weight by 27%, making it one of the lightest wheels of this kind in the market. The vibration-reducing characteristics improved as well, with a difference of up to 70% compared to a traditional spoked wheel.

These results out-performed Sam’s expectations, and didn’t affect the durability and safety of the product. The wheel was able to travel “over 5000 miles without failure or damage” in fatigue testing.

Loopwheels Today

The future looks very promising for Loopwheels as they enter the North American market, speculate on business in Asia, and roll out the latest version of Loopwheels.

Why TECHNIA Simulation

The TECHNIA Simulation are exceptionally proud to be part of Loopwheels’ journey. And we’re sure that you’ll be hearing more about Loopwheels advancements from us very soon.

We speed up and streamline product development processes and drive innovation for Life Sciences organisations.